Soft and hard transparent PVC sheets

In addition to their general properties, P.V.C pavements are characterized by remarkable flexibility, turning them into suitable coating. Diversity of colors, aesthetics and non-absorption of water are other properties of soft opaque PVC sheets, not to mention their mechanical strength, high electrical and chemical resistance.

In addition to their general properties, P.V.C pavements are characterized by remarkable flexibility, turning them into suitable coating. Diversity of colors, aesthetics and non-absorption of water are other properties of soft opaque PVC sheets, not to mention their mechanical strength, high electrical and chemical resistance.Foamed, extruded, ABA-three-layer rigid PVC sheets

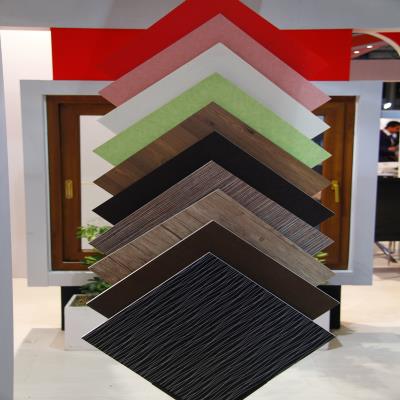

These sheets are chemically foamed with a uniform closed cell structure. The compressed layers above and below the foamed structure provide a uniform, smooth and shiny surface all across the sheet. The outer compressed, foamed shell of this product has different densities. These sheets are produced similar to free foam involving the same coextrusion for creating compressed layers above and below the foamed part. Moreover, these sheets can be offered in various colors and emboss patterns (wood curls) coated with a variety of wood designs. What distinguishes this type of sheets is the more rigid an uniform surfaces compared to free foam sheets. These sheets are produced in thicknesses from 2 mm to 20 mm with a width of 1830 mm.

These sheets are chemically foamed with a uniform closed cell structure. The compressed layers above and below the foamed structure provide a uniform, smooth and shiny surface all across the sheet. The outer compressed, foamed shell of this product has different densities. These sheets are produced similar to free foam involving the same coextrusion for creating compressed layers above and below the foamed part. Moreover, these sheets can be offered in various colors and emboss patterns (wood curls) coated with a variety of wood designs. What distinguishes this type of sheets is the more rigid an uniform surfaces compared to free foam sheets. These sheets are produced in thicknesses from 2 mm to 20 mm with a width of 1830 mm.Different types of PVC sheets

1. Compressed PVC sheets, a convenient alternative to MDF

1. Compressed PVC sheets, a convenient alternative to MDF

2. Foamed PVC sheets with different densities for partitions and suspended ceilings

3. Laminated PVC sheets for decorative purposes